Displaying items by tag: Car & Light Truck Segment Wheel Service

Apex Emission Equipment - Gas Analyser - Manatec / India

Apex Emission Equipment - Gas Analyser- Eco Gas 100 - Manatec / India Eco Gas 100 DESCRIPTION

|

Apex Nitrogen Station - ME - NFS 308 A/MO - Manatec / India

APEX NITROGEN FILLING STATION - ME - NFS 308 A/MO - MANATEC / INDIA ME - NFS 308 A/MO DESCRIPTION

|

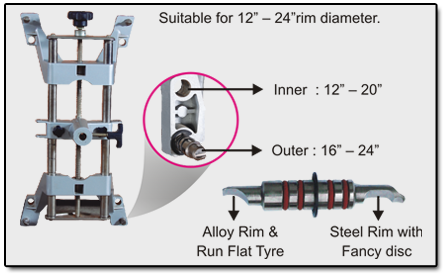

Apex Car TYRE CHANGER - TC XL 40 - Manatec / India

Apex Car Wheel Balancer - WB VL 65 DSP LX- Manatec / India

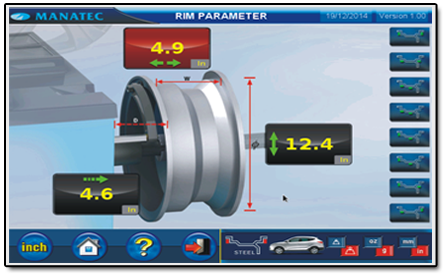

Car Wheel Balancer- WB VL 65 DSP LX - Manatec / India WB VL 65 DSP LX Videographic display DESCRIPTION

ADDITIONAL FEATURES FOR PREMIUM MODELS

|

Features

| Automatic distance & diameter measurement | Automatic width measurement | Mid Centering Device |

|

|

|

| Automatic distance & rim diameter input through distance measuring rod. | Automatic rim width measurement. | Mid centering device for positioning of wheels accurately at center of the rotor assembly. Quick… |

| Optimization Program | Alloy Wheel Functions | Split weight program |

|

|

|

| Optimisation program helps in reduced wheel weights consumption. | 7 Alloy wheel (ALU) functions. | Split weight program (spokes program) helps to split the weight to be hidden behind the… |

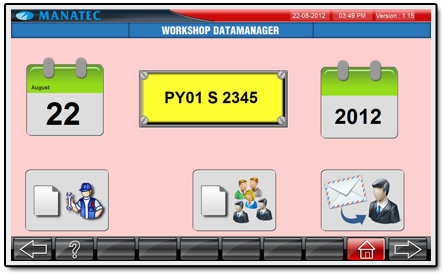

Apex 3D Car Wheel Aligner - FOX 3D AUTO BOOM - Manatec / India

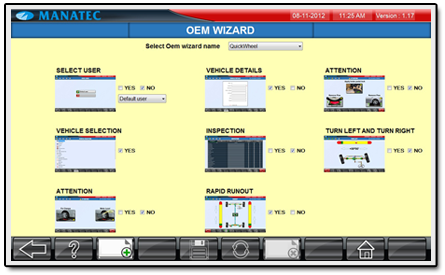

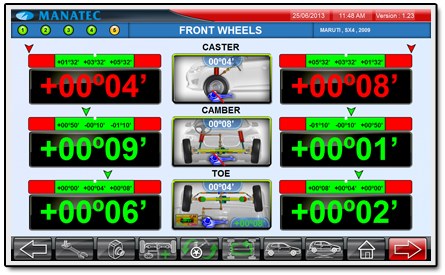

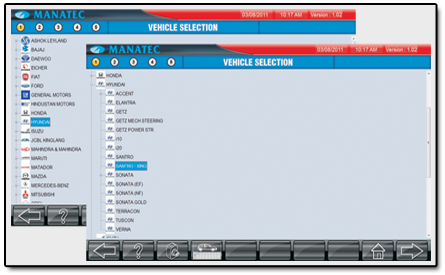

Apex 3D Car Wheel Aligner - Fox 3D Autoboom - Manatec / India Fox 3D Autoboom Automatic camera beam movement synchronized with movement of the vehicle on the lift. All measurements can be done at floor level and adjustments at any convenient level. Provision for manual height adjustment also. DESCRIPTION

|

Features

| QUICK ALIGN PROGRAM | FEATURES MENU | DATA MANAGER |

|

|

|

| Unique OEM wizard program helps in customizing the screens by the technician himself by selecting… | Useful features like vehicle information modification, multi users function, vehicle data updates, unit conversion etc… | Data Manager software to retrieve alignment history by month, year and registration number. Useful tool… |

| LIFT LEVEL COMPENSATION | 2 COLOR BAR CODE | VEHICLE DATA |

|

|

|

| When a scissor lift or a 4-post lift is used for wheel alignment, there may… | Live correction mode helps the operator to correct the alignment with easy 2 color bar… | International vehicle data base with more than 20000 vehicle data including American & European data…. |

| UNIVERSAL WHEEL BRACKET | REMOTE CONTROL (OPTIONAL) | TABLET (OPTIONAL) |

|

|

|

| User-friendly Wi-Fi enabled tablet device to display alignment results and to operate PC from the… | Portable 2.4 GHz Wireless control device to operate the PC from the alignment bay (Max… | Highly user-friendly Wi-Fi enabled tablet device to display alignment results and to operate the PC… |

Car Wheel Balancer 3D- B2000P - Snap-On / Italy

Car Wheel Balancer 3D- B2000P - Snap-On / Italy B2000P DIAGNOSTIC WHEEL BALANCERDESCRIPTION The B2000P is the only automated diagnostic wheel balancing system that offers touchless measurement and analysis. Automatic inputs remove the chance for error and inaccurate results. When combined with precise wheel balancing, the Runout Force Vectoring (RFV) diagnostics assure uniformity based total ride quality.

|

Features

| GAUGE ARM | OVER SIZE SHAFT | SPLIT WEIGHT MODE |

|

|

|

| Semi-automatic data entry and positioning of adhesive weights. | The 225 mm length allows the use of stud-hole flanges and other accessories for almost every type of rim. | Hides Adhesive Weights Behind Two Adjacent Spokes So They Cannot Be Seen From The Outside. |

| EASY WEIGHT TM | EASY ALU TM | QUICKBAL TM |

|

|

|

| Pinpoint laser identifies exact weight placement location for increased accuracy and efficiency. | Touch the rim with the gauge arm to enter the rim dimensions and automatically select the weight balancing mode. | 30% reduced cycle time, less than 4,5 seconds, maintaining the same high accuracy. |

| SMART SONAR TM | VPM TECHNIQUE | RADIAL RUNOUT |

|

|

|

| Automatic, non-contact rim width acquisition delivers greater accuracy and ease of use for a 30% savings in complete process when compared to manual operation.. | Measurement system for high precision and repeatability. | Peak-to-peak and 1st harmonic graphs of wheel run-out are provided for an easy diagnostic of the issues. Rim run-out and matching information are provided when necessary. |

| 3D IMAGING DIAGONISTICS | SMART SONAR TM | VPM TECHNIQUE |

|

|

|

| The type, size and position of a defect in the tire are identified, measured and visualised by non-contact 3D imaging technology | The 225 mm length allows the use of stud-hole flanges and other accessories for almost every type of rim. | Patented automatic Power Clamp™ electromechanical clamps the wheel accurately with a constant force, reducing the opportunity for chasing weight.. |

ON-BOARD DIAGNOSTIC TOOL- PDL 3000™ - Snapon / Italy

ON-BOARD DIAGNOSTIC TOOL- PDL 3000™ - Snapon / Italy PDL 3000™ iNTERNATIONAL EG PDL 3000™ International EG is the latest edition to the PDL 3000™ versionsHARDWARES

FUNCTION

|

ON-BOARD DIAGNOSTIC TOOL- PDL 4000™ - Snapon / Italy

ON-BOARD DIAGNOSTIC TOOL- PDL 4000™ - Snapon / Italy PDL 4000™ iNTERNATIONAL EG The PDL 4000™ International EG had been designed based on latest market requirements to meet the demands of even highly discriminating customers. It pursues the tradition of SUN brand scan tools which all combine user-friendliness with high test coverage and a wide variety of features. With the faster SMX operating system, extended functionality and a larger colour touchscreen display the PDL was not simply revised, but completely redesigned.

|

ON-BOARD DIAGNOSTIC TOOL- PDL 4100™ - Snapon / Italy

ON-BOARD DIAGNOSTIC TOOL- PDL 4100™ - Snapon / Italy PDL 4100™ iNTERNATIONAL EG

With a five-second boot-up and the automatic ID function PDL 4100™ International EG flies - getting you down to business, right away. MAIN FEATURES

|

BRAKE TESTER & TEST LANE - 206/306-RP - Snapon / Italy

BRAKE TESTER & TEST LANE - 206/306-RP - Snapon / Italy Videoline 206/306-RP Test lane for Cars, Vans and Light TrucksProfessional test lane PC based. Modular configuration to meet all requirements

APPLICATIONS: Light duty » Brake Tester & Test Lane

KEY FEATURESRoller set Brake tester - Roller set:

Control unit RP-Box:

Display modules - Workstation:

Display modules - Virtual analogue:

TECH SPECIFICATION

|

|